905.565.0001

Industrial production requires reliable performance, and Schelling’s fk8 delivers. With this saw, you can cut various plastics — productively and precisely. The integrated turning device in front of the saw ensures productivity gains of approximately 15%.

The fk8’s CLEAN-UP system offers efficient chip removal while its dust protection equipment adds cleanliness.

Solid construction and a 45.6 Hp (37 kW) drive form the basis for this modern machine concept.

The Schelling fk6 delivers demands precision and speed for industrial production of plastic sheet materials.

Solid construction and 36.2 Hp (27kW) of power deliver extreme precision with a respectable output. Its numerous details, including 99.5% chip removal, promise all-around productive use for many years.

Because of their respective material properties, sheets made of plastic, composite and other innovative materials require unique processing parameters. The fk4 is optimally loaded with tried-and-tested technology providing worry free production.

Appropriate for all types of materials, the fk4 offers uncompromised precision, intelligent handling and a maximum cutting length of up to 169.3" (4,300 mm).

Its solid machine design and a 28.5 HP (21kW) aggregate provide a stable basis for day-to-day use.

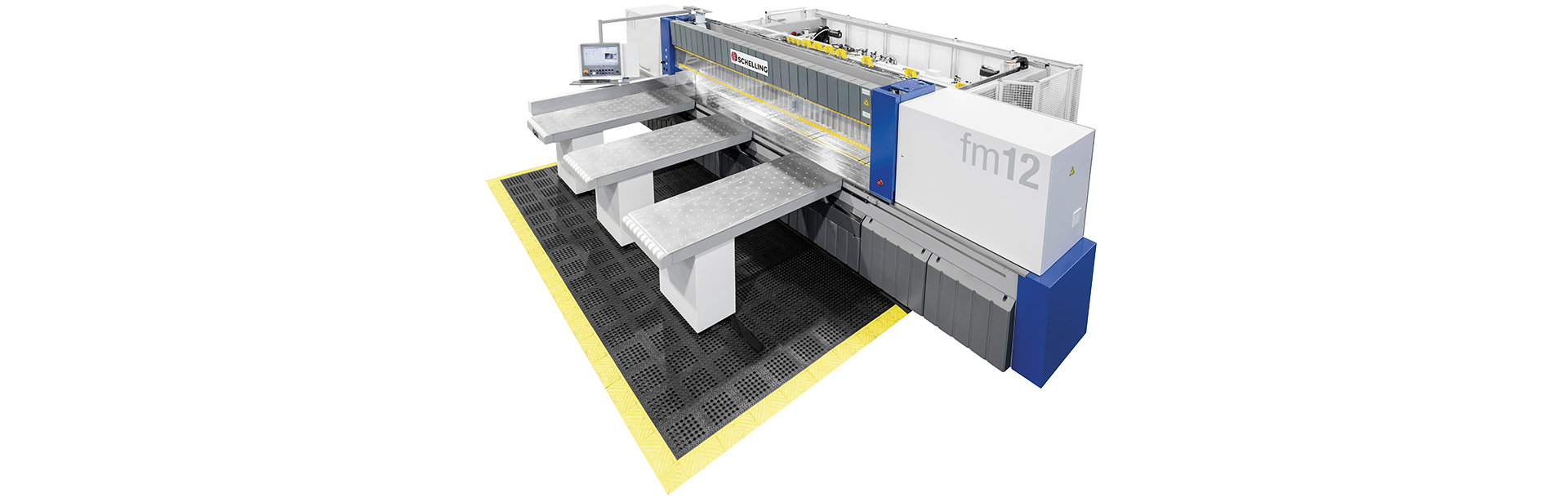

With a book height up to 10” (250mm), the fm12 non-ferrous metal and aluminum plate saw operates with exceptionally high cleanliness in both the complete working area and its peripheral range.

This metal plate saw reliably removes about 99.5 % of chips, which further increases precision and reduces the risk of that plate surfaces will be scratched.

With its myriad of technical features and integration possibilities, the fm12 can stand alone or integrate into automated production.

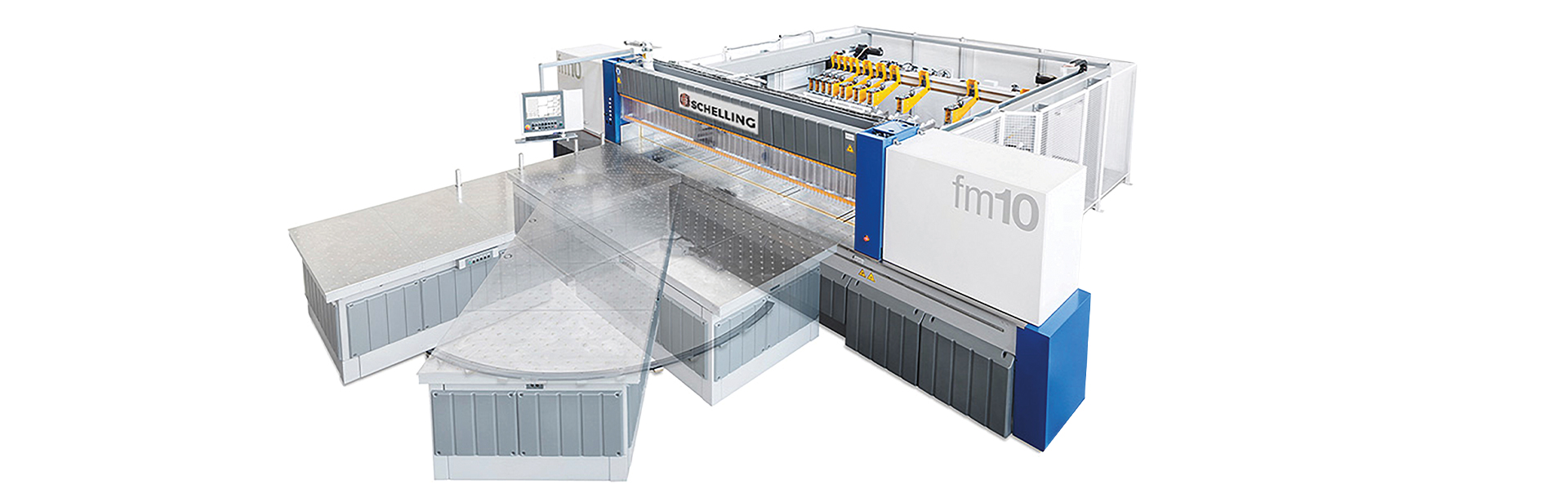

The precision Schelling fm10 is the global benchmark for sawing non-ferrous metals in this segment of demanding industrial production.

With movement on air-tables surfaces, the saw’s massive design supports even more powerful, high-speed motorization, reducing production times. The fm10 features detailed improvements that reduce downtime, increase productivity and improve ease of operation.

In the industrial sector, it takes sophisticated tools to cut aluminum and other non-ferrous metal materials precisely and productively. One such tool is the fm8, which performs consistently and reliably. Its 46.2 Hp (34kW) drive supplies the massive power required for these operations, and clever construction features ensure versatility.

Ideal for dealing with heavy raw materials and workpieces, the fm8’s plate-handling solutions, turntable and powerful air pressure cushion area greatly simplify the process of cutting to size.

Like other Schelling machines, the Schelling fm6 cut-to-size metal plate saw is characterized by precision and cutting performance. The basis for its success is a powerful 36.2 Hp (27kW) digital drive and a solid machine design.

The fm6’s patented CLEAN-UP function by Schelling produces exceptionally clean work conditions. It is highly precise, with 99.5% of chips exhausted, and the turntable allows a 15% increase in production.

Schelling’s fh8 machine construction and impressive motorization masterfully processes a wide variety of timber materials precisely and productively.

Whether large or small batch production, the sophisticated fh8 runs smoothly thanks to the most modern programming and automation.

With up to 37 Hp (27kW) of power, the solidly constructed fh6 offers productive solutions for industrial tasks, delivering the highest degree of precision.

From material feed to finished board part, this wood panel saw’s automation ensures optimum processes. Whether cutting fiberboard, MDF, OSB, HDF, HPL boards or modern wooden materials, the fh6 delivers smooth production. The fh6 is a high performer, ergonomic, safe, precise and fast.

Like the smaller fh4, the fh5 automatic panel saw is a cut-to-size saw for both demanding craftsmen and for those just starting industrial production. Stronger drive, more solid design and enhanced power for book-cutting set the fh5 apart from its smaller relative.

The fh5 automatic panel saw unifies the complete know-how and typical quality characteristics of Schelling. Precision and consistently accurate cutting combined with automation and optimized processes result higher productivity. With a power of 28.5 Hp (21kW), all types of wooden boards – even unusual types – can be processed with ease.

IMA Schelling Group Canada Corporation

3400 Ridgeway Dr., Unit 8 Mississauga, ON L5L 0A2

© 2025 IMA Schelling Group CA. All Rights Reserved.

Site Designed By:

Gotham Industrial Marketing